Inventory Maintenance

WHAT DOES IT MEAN TO ESTABLISH AN ORDER TO LEVEL (OTL)?

An order to level is the maximum quantity of an item that you wish to have on your shelf at any given time.

HOW IS THE QUANTITY DEFINED?

The number of units you dispense daily multiplied by the number of days' supply you wish to have on the shelf.

TIPS:

1. Write OTLs on the shelf label.

2. Walk your shelves daily ordering only those items that have fallen below the designated OTL.

To establish your Order to Levels, consider following either the Basic or Advanced methodology.

METHOD 1 — BASIC

| Establishing Order to Levels | Look at your actual dispensing usage (or purchase history usage if dispensing history is not easily accessible). | Determine how many days' supply of an item you wish to carry at any given time. | Filling less than 100 prescriptions/day, consider a 3 day supply | Filling 100-300 prescriptions/day, consider a 4 day supply | Consider exception items that may warrant a different days' supply, such as high cost or fast moving items. | High Frequency Items Reports provide you the ability to identify items that you may be purchasing with too high of a frequency relative to the expected frequency for the item category. |

|---|---|---|---|---|---|---|

| Calculating OTL Levels | The number of units you dispense daily multiplied by the number of days' supply you wish to have on the shelf. | For example, your report history from May 1 – July 31 shows you dispensed 4680 tablets of Metformin 1000mg tablets. There were 92 days in that time frame; however, you were closed 12 of those days. Your daily average was 4680/80=58 tablets per day. Round that up to 60 tablets. | You order daily from McKesson and you have decided that you want to carry a 3 day supply on the shelf which would be 180 tablets. | You carry 100 count bottles of this product; therefore, you would place a 2 (100 x 2 = 200) on your shelf label. Anytime your stock fell below two full bottles you would order the amount that would take you back to having two full bottles on the shelf. |

Write the OTL on your shelf labels. |

Note: Be sure to account for days within the reporting period in which you were closed to get an accurate daily movement average. |

| Managing OTL Values | Consider the many reasons there may be adjustments during the year. |

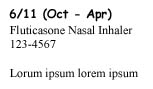

Seasonal adjustments — Adjust levels seasonally when you anticipate an increase in product usage. This will be based on historical usage data from your pharmacy system and/or McKesson ConnectSM data. |

|

Change in stock bottle size: Update the shelf label for a new item when you switch bottle sizes to reorder a larger or smaller size of the item. | Normal business growth: Adjust OTLs due to increase/decreased dispensing. |

|

METHOD 2 — ADVANCED

WHAT DOES ESTABLISHING REORDER POINTS (ROPs) AND REORDER QUANTITIES (ROQs) MEAN?

ROP and ROQ levels are established based on actual dispensing usage (or purchase history usage if dispensing is not easily accessible).

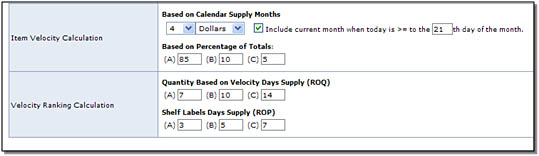

| Establishing ROP and ROQ | Velocity Ranking (A/B/C value) can be assigned based on top-down dollar spend per item. |

Focus on "A" items (those with the highest investment) for the biggest impact to inventory management. Lowering "days supply" numbers for the higher-investment ("A" items) allows you to turn those products faster and maintain a lower investment of dollars in those items at any point. |

Increase some lower-investment ROP/ROQ vaules (and therefore inventory levels) to avoid costly daily processing of those products. |

|---|---|---|---|

| Calculating ROP and ROQ |

To determine an ROP, calculate your weighted item movement (with more emphasis on recent dispensing to capture trends) down to a daily quantity and then multiply by the number of days you wish to keep on hand. To determine the ROQ, follow the process above for the ROP, except use the number of days you wish to order after reaching the ROP. |

Example: You dispense 200 Rx's per day, and decide that you want to maintain a 5 day supply as your ROP and order a 10 day supply when it is reached. You run a 120/day item movement report. This report shows total movement of 6000 tablets for that period (1800, 1600, 1500, and 1100 respectively for each month going back in time). You can weight the calculation by adding .4(1800) + .3(1600) + .2(1500) + .1(1100) or 720+480+300+110=1610, which divided by 30 results in a 53.67 per day usage. Multiply times 5 for a ~268 ROP and by 10 for a ~537 ROQ. If this product is dispensed in bottles of 100, then your package-level ROP is ~2.68 packages and your ROQ (order value upon reaching ROP) should be ~5. NOTE: Be sure to account for days within the reporting period in which you were closed to get an accurate daily movement average (the simple example shows division by 30 but you can adjust that accordingly to subtract days not worked within the period). |

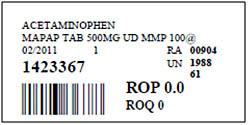

Write Reorder Points (ROPs) on your shelf labels or you can use McKesson Connect to print shelf labels with ROP values already on them (see example).

|

| Adjustments to ROP and ROQ Values |

1. Seasonal Adjustments — Although using a weighted value like McKesson Connect helps, you may wish to adjust levels seasonally when you anticipate an increase in product usage. This will be based on historical usage data from your pharmacy system and/or McKesson Connect data.

|

2. Change in stock bottle size — Update the shelf label for a new item if you switch to reorder a larger or smaller size of the item. |

3. Normal business growth — Adjust ROP/ROQ due to increase/decreased dispensing. Adjusting levels to match your dispensing will reduce out-of-stock occurrences which will improve customer satisfaction levels and drive increased cash flow and profitability. This will automatically happen if using weighted values, but you may need to accelerate if there is a very fast up-tick in purchases of a particular product. Again, the days' supply value on the individual items can be adjusted in McKesson Connect.

|

NOTE: For those unable to get the necessary dispensing data, McKesson's Asset Management functionality is based on purchase history (vs dispensing), but the concepts for velocity assignment and calculations for ROP/ROQ are the same otherwise and it can calculate values that are exportable from the McKesson Connect to print shelf labels with ROP values already on them (see example).